There are many benefits to the technological advances that have occurred within the industrial cleaning industry. These advances in technology yield data that can be used for many purposes. Adding machines to your fleet that have innovative technology from Intelligent Cleaning Equipment means you have all the information about that machine’s progress and effectiveness at your fingertips.

The power behind the technology is the ICE lithium-ion battery (LiB), which means your battery worries are over. LiBs store and then release energy, they are made of the lightest metal, have a higher energy density, and contain no poisonous metals, such as lead, mercury, or cadmium. On average, lead-acid batteries need to be replaced every 12 months. This means parts, service, and labor costs of anywhere from $1200 to $1600 per replacement/per machine. Not many colleges and universities have the budgets for that type of maintenance.

In contrast to lead-acid batteries, LiBs are the most reliable and safest batteries available today. Further, LiBs are a greener choice, take a fraction of time to charge, and last eight times longer than traditional lead-acid batteries, which means job efficiency and a reduction in overall costs.

The Technology

ICE’s automated machines have innovative technology that allows the user to effortlessly program the autonomous machines using the comprehensive but simple AI technology and easy-to-use dashboard. Users can program these machines to start and complete a specific cleaning route; in fact, it is possible to program up to 60 customized routes. Once the machine is programmed with stored routes, the operator can choose any one of these paths and deploy the machine. Further, from the machine’s dashboard, the user is able to not only choose a route, but can also request a report, access troubleshooting resources, and view training videos, which is an excellent tool when onboarding new staff.

ICE has created the perfect balance of advanced yet practical technology with an interface that is easy to use, program, and learn, which also has a cloud-based data center for accessing important usage analytics.

The Data from the Technology

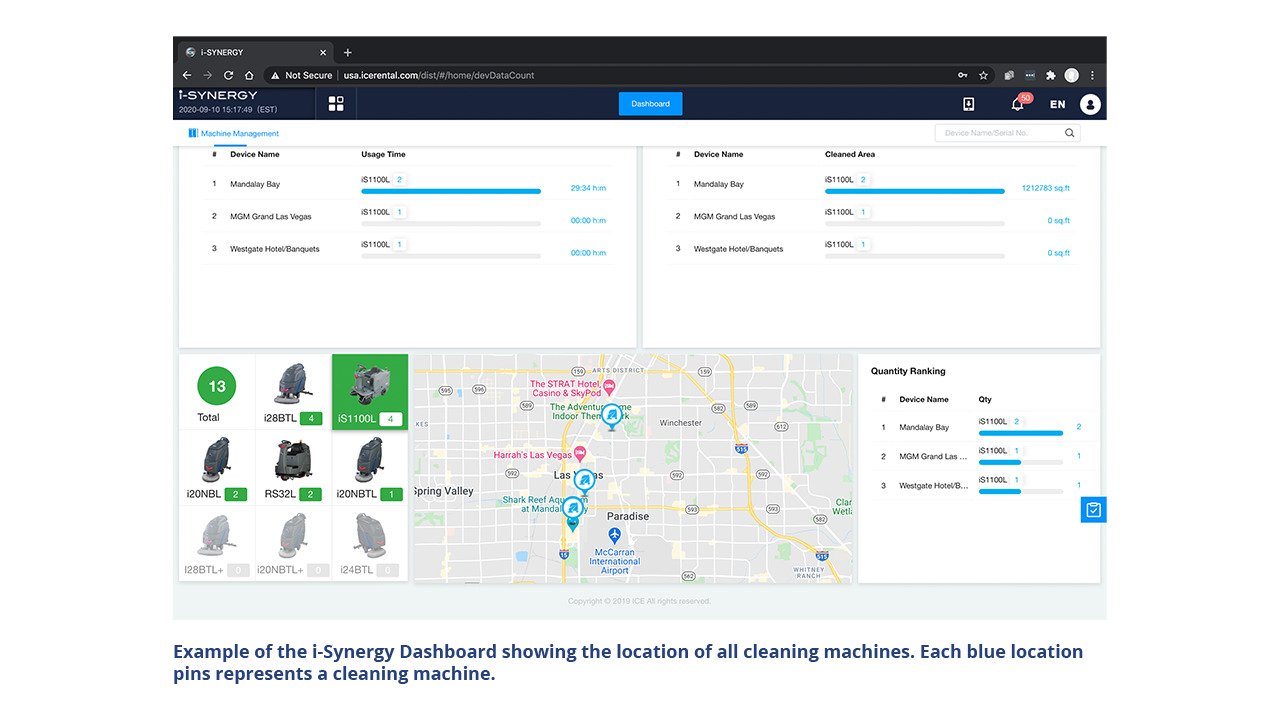

This advanced technology improves efficiency and effectiveness, and it also yields some important data that could positively impact your bottom line. One of the most critical pieces of information that some ICE machines gather is that of machine run-time and square footage covered. This is the biggest component to factoring for employee needs and future budget planning. Also, it is very common within many industries to employ contractors to conduct after-hours cleaning services. The benefits of having this type of detailed insight on machine usage is extremely helpful in regard to tracking the performance of your contractors. Let’s say you are on the East Coast and have machines and staff on the West Coast. Using this data, and the GPS capabilities, you can see the exact location where each machine is in real-time. You can also view confirmed clean areas and the running-time of the machine. Having this type of information can be used to reorganize schedules, redeploy workers to other necessary locations, and better plan for other cleaning and maintenance procedures.

Maintenance Supervisors, Superintendents, and Facilities Directors have access to this data and can also choose which employees access which machine data. For example, if you have six machines in your fleet and you would like to give one employee access to all six machines, another employee access to machines 1 and 4, and a different employee access to machines 2 and 3, you have the capability of doing so. The data dashboard is extremely customizable and data and reports can be accessed via the mobile app or a computer.

Once you and your employees are all set up, the data dashboard displays all of your machines on one screen, including their GPS locations. Choose a machine that you want to view data on, and it is all there and perfectly visually organized for you: routes cleaned, square footage covered, operating time, heat maps, and battery information.

Reports

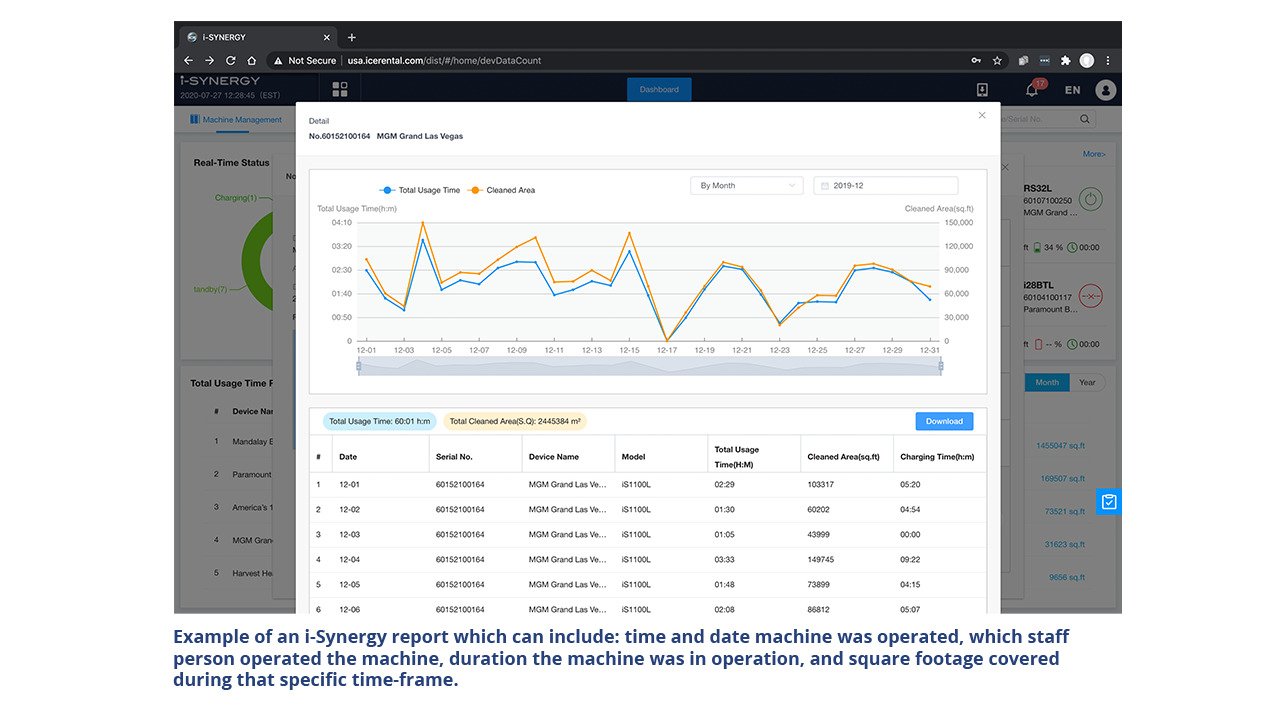

To put this data to even better use, it is possible to view and download historical usage information. This is, again, helpful for everyone from employees to facilities directors to operations executives. The reports can include: time and date machine was operated, which staff person operated the machine, duration the machine was in operation, and square footage covered during that specific time-frame. Also, if your machines are autonomous, the historical usage reports allow you to see whether manual or autonomous mode was deployed. This information is helpful because many newly implemented autonomous machines are not being used to their fullest potential. This is sometimes due to lack of awareness surrounding the benefits of automated machinery. But once employees are comfortable in knowing that the machines assist them in completing jobs more efficiently and effectively, then this usage data can be used to track usage and also to implement autonomous (versus manual) usage goals.

Another beneficial feature of the data is predictive failure warnings if there is a malfunction with the machine. When a component is failing, for example if a back-motor or scrubbing head is not functioning properly, an alert is sent to advise of this component failure. The notifications and alerts can be seen by the end-user on the ICE smart phone application. This means right away you can act on any problems by calling for assistance, which minimizes downtime. Our service-line professionals are fast and friendly and can sometimes even diagnose the problem over the phone and get you back up and running. If service does need to be performed, ICE stands behind all of its machines and has the industry’s best warranty program for industrial cleaning machines.

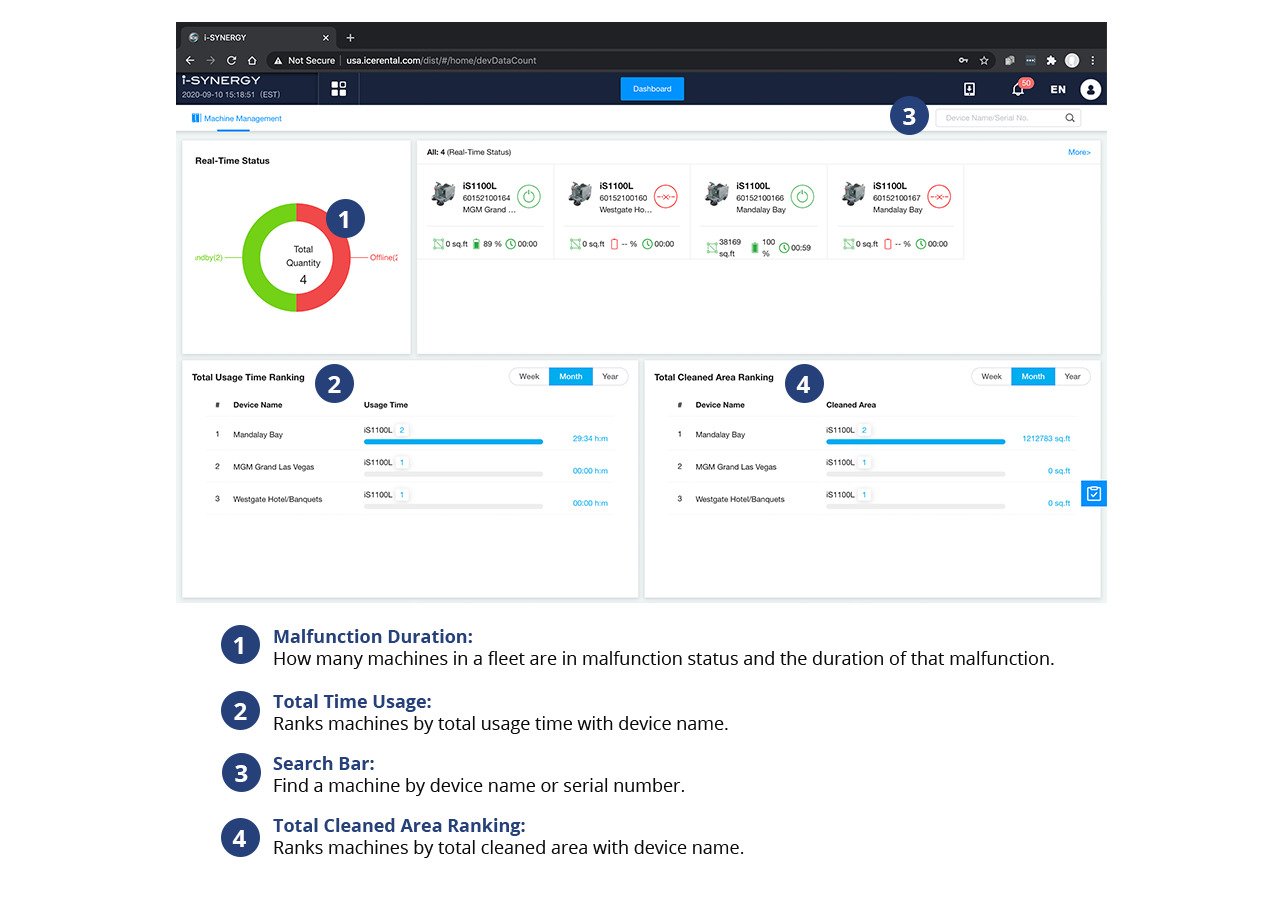

When viewing the dashboard, you will see the status of the machines, how each one has been used in the last 24 hours, each machine’s ranking based on coverage and location, and also whether the machine is on standby mode or is offline. This, as well on the app, is also where any malfunctions will be displayed. If a malfunction is displayed on this dashboard, simply click on that machine and receive the information as it relates to the malfunction.

Again, all of this data, when used to its greatest potential, offers not only insight to usage, but the historical data can be used to reorganize your labor force and plan for and schedule routine maintenance. Another great benefit of having this insight is having the capability of knowing the best times to rotate machines. All this means your fleet lasts longer, which affects the bottom line.

Leave A Comment